Aug 26, 2019 David Weber Academy

Resin Epoxy - Important Points

Used in a wide range of industrial, craft and surf industries, the resin epoxy is today the world's highest performing resin available on this market.

The use of compounds is not new. In fact, there is a need to create this concept before you start talking about it. Compounds are “materials” formed by the joining of others in order to obtain a final product with different characteristics. Compound studies are divided into two phases: (1) Matrix and (2) Reinforcements. The matrix is generally a continuous material that involves the reinforcements. In this sense, here in the case of construction processes, Resin will be our Matrix, while the Reinforcement will open the space for infinite options and possibilities.

Depending on what we are building, we need the specific features to get or get the best performance from the product, and it is in this context that we choose different “Reinforcement” options. You can use Aramid Fiber (Kevlar), Carbon Fiber, Fiberglass, Cotton Fiber, Aerosil, Rovin, Sawdust, among many others.

Epoxy resin is far superior to polyester resin, used on most surfboards. In addition to being much less toxic, it has greater mechanical strength, and also presents itself as a thermoset polymer, while a polyester resin fits as a thermoplastic polymer. This means that when providing high temperatures, polyester resin tends to melt, whereas in epoxy resin it does not. However, an epoxy resin is also not 100% safe for our health. Therefore, we must always make sure that we are working with it, wear a suitable respiratory mask, as there are a lot of volatile compounds that are released during mixing, which are partly harmful to our health (even if it has no smell)!

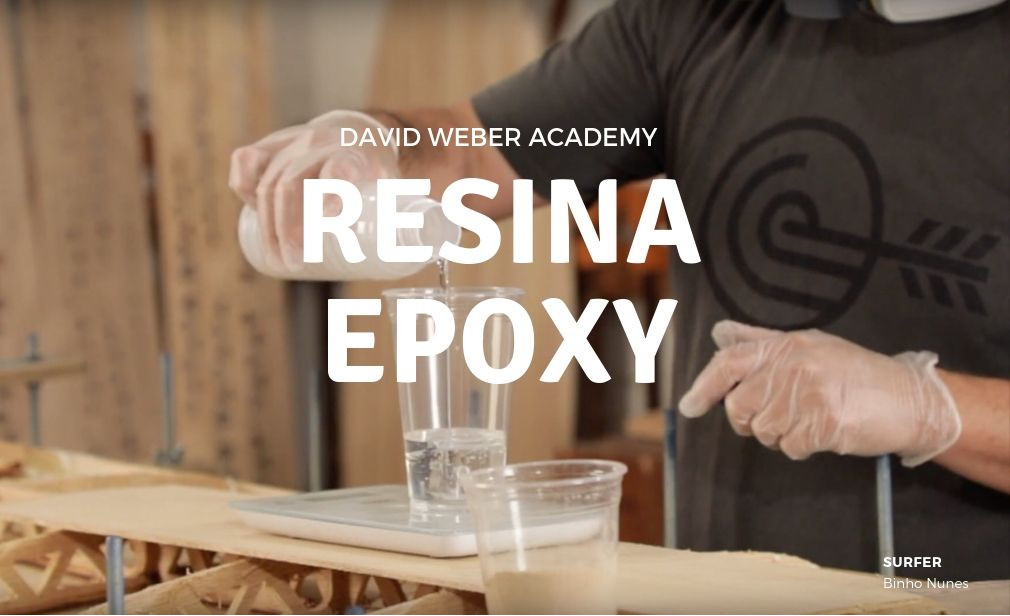

In the video below, I will talk about some important points about the preparation of epoxy mixture.